Rug Weaving Looms

Here is information about weaving rugs and what makes a good loom for weaving rugs. The links in the table above will help you navigate to various sections and topics about rug weaving and rug weaving looms.

Rug Loom Frames

The traditional handloom frame is tall, strong, easy to assemble, comfortable for weaving, comfortable for threading and deep enough to give better results. The framing pieces are large and the large ratchet handles make turning the beams and tightening the tension much easier. The frame usually has a knee beam and a foot rest. The frame has wedges for ease of assembly, is very deep and is convertible from counterbalance to countermarch. Laminated beams made from straight grain wood keep the loom square. The overall look is of a serious piece of wooden equipment.

Hanging Beater

The traditional loom has a frame with a tall castle, which allows for a hanging beater. The beater is tall and will give a longer, easier stroke. It is quiet, and doesn't require a lot of strength. You don't have to lift the weight of the beater as you beat. This means that the beater can be heavy and the weight is doing most of the work. You can beat a heavy beater without much effort. Hanging beaters sit in a cradle so they can be adjusted to beat perfectly square and you can vary the distance it sits from the breast beam. You can advance the beater as you weave so you don't need to advance the warp so often.

Treadles

Treadles attached in the rear give better leverage and easier treadling. They are tied with cords so they are adjustable in height. Deep looms give you long treadles, which are easier for adjusting sheds.

Beams

Cross beams and beaters should be made from laminated wood to make them stronger and keep them from warping. The uprights which hold the breast beam get the most stress and should be laminated. There will be a strengthening bolt through the upright where the breast beam is attached, as this part of the loom takes a lot of stress from warp tension. The circumference of the laminated cloth and warp beams should be from 9" to 12". Warp beams made for production weaving, can be removed from the loom frame without taking the frame apart.

Fabric Protector (breast batten)

A traditional loom has a fabric protector, which is a thin board placed outside the breast beam. This allows you to sit very close to your weaving without touching the weaving, giving you better posture. This board when raised slightly, acts like a fence to keep shuttles from falling off the loom when you are beating. This is especially helpful when weaving with more than one shuttle.

Shafts and Heddles

The kind of heddles your loom has is determined by the type it is. Jack looms need weight and so they have the heaviest metal heddles. Wire heddles are lighter than the metal ones. Counterbalance and countermarch looms do not need to add weight to the shafts, so they can use string heddles or Texsolv heddles, which are quiet and cause less wear on the warp threads. Texsolv heddles come in many sizes and can be put on most any loom. If your shafts do not have sides, any size texsolv heddle will fit.

Loom Depth and Comfort

Traditional looms have generous depth, giving you easier treadling. When the treadling is easier, you are more comfortable, can weave more easily, and you will not tire as you weave. This depth will provide a better shed and lessen the strain on the warp. This large frame also gives you plenty of space to get inside for threading and sleying.

Knee Beam

A knee beam is absent on most small looms. This beam is located near the weaver's knees when sitting at the loom. It raises the woven material and protects it from the weaver's knees.

Benches that are comfortable

A proper bench the correct height is essential for comfortable weaving, as well as more accurate, faster and less tiring weaving. Treadling is very light on a traditional loom, so there is no need to have a slanted bench or to sit teetering on the edge of the bench. You can sit comfortably on the bench and you will not tire as fast. The bench should allow you to sit very close to the loom. Sometimes your balance will be the best if you are actually touching the breast beam as this will support your back. If you must lean forward to get closer to your weaving, your balance will not be good, your posture will not be good and there will be tension in your lower back.

Bench Height

The loom's breast beam height should be at least 33" and is commonly 35 or 36". Your bench should be at least 27" high, with adjustability for lower settings. If your breast beam is lower than 33", your knees will be too high. This can cause poor posture and it can be tiring and uncomfortable to lift your legs to treadle. To read more on benches and comfort visit: Benches

Treadling with ease and comfort

Most weavers learn to weave without looking at the treadles to find the correct one. The first step to achieve this is to take your shoes off. Most treadles are too close together for weaving with shoes on. If you have to push so hard on the treadles that you must wear shoes, then the treadling is too hard. The most important recommendation for maintaining balance and comfort while treadling is to use both feet alternately. If you are using only two treadles, tie them in the center so that you will use both feet. If you are using more treadles, plan your treadling so that you can alternate feet or weave certain sequences with each foot. If you are weaving on a jack loom with many shafts, warp faced, or a wide warp, you may have difficulty with lifting the shafts. It might help to tie up the treadles to just one shaft and use two feet for treadling. If treadling is so hard that you need to stand to weave, the treadling is too hard. If you are tall you may need to put blocks of wood under the feet of the loom, so that the whole loom is taller. Then lengthen the cords which tie up the treadles.

Warping for perfect tension

Good warping techniques will produce a rug which is square. The most important part of the warping process is the winding and beaming of the warp. The winding should be done carefully in bouts which do not make more than six to eight inches of the warp. The warp beam should be large so that the warp will not have to build up very much. A beginning rug weaver should warp for only one or two rugs at a time to assure perfect tension. The warp should be beamed as tightly as you will be weaving which is very tight. The warp on the beam should look like a perfect cylinder. To achieve this you need to beam with many sticks. Long warps will need selvage papers.

Selvage papers

Selvage papers are described in Ulla Cyrus's book, Manual of Swedish Hand weaving and are used for beaming long warps. They are made from heavy paper which has been folded so that the folded section has eight layers with an extended edge which has one layer. The eight fold section lies outside the selvage threads, giving support for the beaming sticks which follow, keeking them parallel to the beam. Use a paper 16" x 24" and fold the long edge 1/4 in toward the center. Fold this section two more times so that it is eight thicknesses and the other edge is one thickness. The single thickness is placed under the selvage threads as the warp beam is turned and the eight fold section is outside the warp. This thicker side gives support to the sticks to keep them from bending. Selvage papers should be used with beaming sticks. Ordinary paper as a replacement for beaming sticks is not recommended.

Beating a Tight Rug

It is not difficult to get a tight beat on a large counterbalance or countermarch loom. On small looms it is more difficult. The short underslung beater attached to the bottom of the loom requires more strength for beating. Of course, you must always put your hand in the center of the beater for a level beat. If you cannot use a deeper loom with a hanging beater, try these things:

- Advance the warp more frequently.

- Use a temple so that draw-in does not hamper or resist the beat.

- Be consistent in the angle you place the weft across the warp.

- Add weight to the shafts if it is a jack loom.

- Add weight to the beater if it is lightweight.

- Cut rag wefts into two strips instead of one.

For more information on beaters, visit Swedish Looms

When to Beat

A tight beat might require beating two or three times, beating on a closed shed and again after changing the shed. You can try beating first on an open shed, but often this causes large weft loops at the selvages. A closed shed will hold the weft where you want it to be.

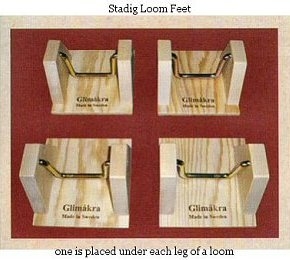

Stabilizing the loom

There are several things that you can try to keep the loom from moving when you beat. Stadig loom feet are frames with small cradles which keep the loom from moving. No other solution works as well as they do. If you have a cross piece on the front or back of the loom which is close to the floor, small blocks of wood will raise the loom an inch or two to allow for use of the Stadig loom feet. Rubber backed carpet will work but it may stick to your floor. A long piece of wood placed between the loom and the wall can work, but you will need to protect the wall and the loom from surface damage. Using this can also damage your loom frame.

Selvages and Craftsmanship: How to get a square, tight, flat rug with perfect selvages

A beautiful, square rug that will lie flat on the floor requires that all parts of the warping and weaving are done correctly, but one of the most important things that you need to do is to use a temple. Not only will it give you better selvages, but it will produce wefts that are straight across the rug, giving you a finished rug that is square. The purpose of a temple is to improve the quality of the weaving, but it will also increase your weaving speed. It will keep selvage warp threads from getting worn or broken, give you a tighter weave, a more even beat and make the beating easier. When not using a temple, the weaving becomes narrower than the warp threads in the reed. This is draw-in or narrowing of the weaving. This causes the warp threads at the selvage to be to closer together. This closer sett means that the weft cannot be beaten down as much as in the center of the rug and the selvages will build up. You get a rug which is not tightly beaten and the weft stripes are not straight across the rug. A temple will not correct this problem, but it can prevent it. If you try to prevent draw-in by leaving the weft slack at the selvages, your wefts will be loose at the selvages. Loose weft at the selvages causes less warp take up and the selvage warp threads will become loose. Eventually the weaving becomes more difficult. The temple will prevent this, so you can keep your weft tight at the selvages without drawing in. Weighted selvages are sometimes used as a substitute for using a temple, but this will not solve the draw-in problem. Weighted selvages should not be needed if you beam your warp tightly. Floating selvages are used primarily for catching the edge warp threads on reverse twill weaves or two shuttle weaves. It is easier to weave without them.

Shuttles for rug weaving

For rug weaving, ski shuttles or double ski shuttles work very well and hold more weft. They can be thrown across the warp because the ends are curved inward like a ski. They do not require a very large shed. Select the ones which are not too tall as they are difficult to throw through the shed. For more information on shuttles visit: shuttles

Types of Looms

Counterbalance and Countermarch looms

Being the traditional type of loom used for rug weaving, tying up a loom to counterbalance or countermarch gives advantages for rug weaving. When a shed is made some shafts go up and the rest go down. All of the shafts are responding to the weaver's foot, giving responsive, quick and quiet treadling which is necessary for rug weaving.

The shed

The pressure you put on the treadles regulates the size of the shed. You can open a small shed by giving a light touch or a larger shed with a stronger touch on the treadles. Small sheds give much nicer selvages, but you can get a large shed when you need it. You can tighten the warp tension as much as you want and the tension on the warp threads is the same on the top and bottom of the shed at all times. Pressing on the treadle brings some shafts up, but at the same time, holds the others down. There are no shafts left to keep their place only by their weight, as with a jack loom. A clear shed can be made even on closely sett or sticky warps. A large clear shed can be made even on a very tight tension by pushing harder on the treadles. The wefts can also be beaten in more securely because the warp travels straight from the breast beam to the back beam.

Loom Tie Ups

Counterbalance looms commonly have from two to ten shafts, but more commonly have four. If you want three, five or more shafts, you need to tie them up differently. This is done after the warp is tensioned, and you will need to use more pulleys or horses. But most weavers purchase the countermarch for their loom when they want to tie up more than 4 shafts. When weaving three shafts against one, on a loom which is more than 3′ deep, the shed will be very usable on the counterbalance tie-up. If the loom is a deeper loom there is no problem with unbalanced sheds. With a counterbalance tie-up on a shallow loom, the one shaft that moves opposite the three will have a tighter tension. You can adjust this by changing the height of the shafts. Counterbalance looms have a way to adjust the height of the shafts. The countermarch tie-up will give a perfect shed with unbalanced tie-ups. On a shallow loom a countermarch tie-up is preferable. Countermarch Looms are a more recent tie-up system than counterbalance. It gives advantages for the tie-up of more than four shafts. An extra set of lamms gives an independent tie-up of each shaft. You can easily add treadles and shafts. Since tie-ups are done from the countermarch jacks on top of the loom's castle, there is usually a hanging beater attached to the castle.

Jack Looms and Rugs

Not a popular tie-up system for rug weaving, this type of loom is popular mainly in the US where it was created in the early part of the 20th century for handloom weaving. It is the type of loom used for table looms and small folding looms. On jack type floor looms, the shafts are moved by jacks which are commonly placed below the shafts. This type eliminates the need for the castle frame above the loom and is the reason jack type looms are short.

The Jack Loom Shed

The shafts work by being placed a few inches below the usual path of threads going straight from the breast beam to the back beam. This lower position is maintained by having the shafts heavy enough for their weight to resist the tension on the warp threads. Weaving with a slightly looser tension is needed to keep the shafts down, especially on a wide warp. You must observe that the reliance on gravity to hold heavier shafts down, rather than having them attached to the treadle, gives some disadvantages which are most notable on wider or tightly tensioned warps. To read more on Jack looms visit: Jack looms

For more information on selecting a loom visit: selecting a floor loom